Partners’ success and satisfaction

is Sinoec priority!

Who is Sinoec

With the support of our professional team, in Sinoec Chemical Group we focus on raw material and chemical trading. The company is involved in the import, export, and tripartite trade of chemicals and raw materials for international markets especially in Asia and Europe. The company has close cooperative ties with many major chemical suppliers which enable us to have access to information on foreign research and development trends and developments in different markets. Thanks to these connections and experiences, Sinoec can take part in rubber plants to provide technical, commercial, and procurement services for its clients.

In Sinoec, we believe in integrity and trust. Our main commitment is to contribute to bringing the greater success of our partners with the best quality and with the most reasonable price. The accurate knowledge of our staffs, which is the company main asset, is a result of our previous successful experiences with our partners all around the world.

Since we recognize our partner’s success and satisfaction as our own priority, we proactively seek opportunities and enjoy going above and beyond to achieve extraordinary results, build lasting relationships, and exceed expectations.

Considering our values and our mission, we have consistently planned and strived to be the most well-known and the preferred choice both for the customers and the suppliers.

Sinoec Area of Expertise

Natural Rubber (NR)

Natural rubber is obtained from latex, a natural secretion of certain plants. Latex is composed of long polymer chains that must be partially broken between rollers or rotating blades to soften or grind the rubber before adding compounding ingredients. Compounded rubber is then sheeted, extruded in a specific shape, applied as a coating, or molded for vulcanization.

Butadiene Rubber (BR)

Butadiene rubber or Polybutadiene rubber (BR, PBD) is one of the cheapest and largest-volume synthetic general purpose elastomers which is sometimes used as a substitute for natural rubber (NR). It is produced either by anionic polymerization or by coordination polymerization of 1,3-butadiene typically in a non-polar solvent.

Styrene-Butadiene Rubber (SBR)

Styrene Butadiene Rubber (SBR) is the most common and economical synthetic rubber compound available and is used in a broad range of industrial applications. Styrene butadiene rubber is a polymeride created from styrene and butadiene. Oil refineries derive styrene and butadiene from petroleum, then combine 25% styrene with 75% butadiene to make SBR.

Emulsion Styrene-Butadiene Rubber (E-SBR)

Emulsion Styrene-Butadiene Rubber is one of the two major types of SBR. It can be produced by free-radical emulsion polymerization of styrene and butadiene either at 50 to 60°C (hot emulsion SBR) or about 5°C (cold emulsion SBR). The hot emulsion SBR process has exception processing characteristics such as good dimensional stability and good extrusion characteristics. On the other hand, Cold SBR has better abrasion resistance and, consequently, provides better tread wear and dynamic properties. It also exhibits superior mechanical properties such as tensile strength compared to grades produced by the hot emulsion polymerization route.

Solution styrene-butadiene Rubber (S-SBR)

Solution styrene-butadiene Rubber is another type of SBR. SSBR is produced by termination-free, anionic solution polymerization of styrene and butadiene with alkyl lithium initiator (e.g., butyllithium) in a hydrocarbon solvent, usually hexane or cyclohexane.

Styrene-based Thermoplastic Elastomer (SBS)

The styrene-based thermoplastic elastomer (SBS rubber) is a triblock copolymer based on styrene-butadiene, a unit of long sequence of the main chain, and then covalently bonded to each other formed by the copolymer. SBS obtained by the polymerization of a mixture of styrene and butadiene.

Butyl Rubber

Butyl rubber is a synthetic rubber compound or copolymer composed of isobutylene and isoprene. Isobutylene is a chemical compound consisting of methyl and propylene while isoprene, consisting of menthyl and butadiene, makes the rubber unsaturated and able to vulcanize. Butyl rubber is one of the commonly-used synthetic rubber compounds on the market.

Ribbed Smoked Sheets (RSS)

Ribbed Smoked Sheet Rubber, commonly known as RSS, is a natural rubber that comes directly from the latex of rubber trees. The coagulated latex sheet sheets are visually graded based on certain parameters and then packed in bales.

Ethylene Propylene Diene Monomer Rubber (EPDM)

EPDM rubber is a type of synthetic rubber. It is extremely durable and flexible and therefore has a wide range of applications. EPDM is a copolymer with elastomeric properties, which means it is a polymer which is both viscous and elastic. If stretched, it will return to its original shape. Its two main components (ethylene and propylene) are both derived from oil and natural gas.

Buna N Rubber

Buna N rubber is a synthetic rubber compound that is also known as standard Nitrile rubber. The compound comprises co-polymers: acrylonitrile and butadiene. Acrylonitrile is a volatile organic liquid. Butadiene is a synthetic chemical compound. When mixed, these two polymers react and produce one of the strongest oil-resistant rubber compounds currently available.

Urethane Rubber

Urethane rubber, also known as spandex, is a polymer containing a urethane block for strength and heat resistance as well as a polyether block for elasticity. As a result, urethane rubber is considered one of the most versatile rubber compounds available. Urethane rubber is resistant to abrasion, powerful impacts, ozone, chemicals, and radiation.

Sinoec is also capable to provide Polymer materials like Polyisoprene and more for its valuable clients.

Applications & Industries Served

Bearings and Bushings

Gaskets & Seals

Aerospace

Automotive

Chemical Industries

Oil & Gas

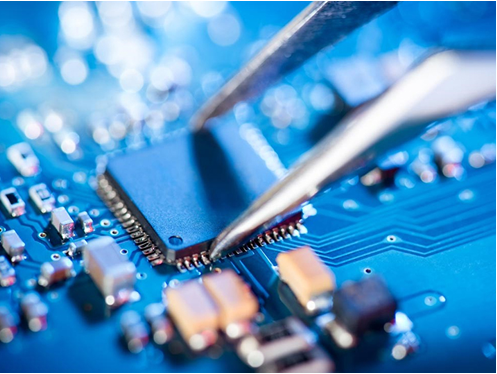

Semiconductors & Electronic

Hydraulic

Find Sinoec